OUR QUALITY

OUR QUALITY

We are a noteworthy manufacturer of a superior quality Domestic Door Closer. Aluminum Extruded Body Door Closer, Hydraulic Door Closer Our offered door closer is manufactured using the finest quality raw material that is sourced from the authorized vendors of the market. Furthermore, we examine this door closer against numerous parameters to ensure its flawlessness. Hydraulic Door Closer Provided Our clients Kyoto Brand is widely demanded in the global market. We are an lSO 9001:20015 certifled company admired name in the industry field for its remarkable features. Our clients can avail this door closer from us at nominal prices. . headquater at the Rajkot - Gujarat - India.

QUALITY ASSURED

VishWas industries We have always been able to maintain a very high standard of quality in exports of Sanitary Hardware Products Universal Door Closer of Aluminum Extruded Body Door Closer, Hydraulic Door Closer Range and has acquired a formidable reputation worldwide. The well-known infrastructure is complete with all the modern facililtes managed by the most Vishwash Industries We very well blend various aspects of technical innovation, development of infrastructure, globalization wtth a heightened awareness of the environmental protectton, We very well follow a market driven philosophys

In-house Manufacturing Unit & Dexterous Workforce

We To Guarantee World Class Stringent Quality Measures ISI/ASTM Specifications.

We Use Fresh Techniques & Technologtes

We Can Make Custom Based on Customers Nedd Size & Shape

We offer more possibilities to meet your every need.

Vishwash Ceramic Industries Sand & Shot blasting Surface Cleaning Services (Job work)

Owing to the presence of our experts, we are providing Sand Blasting , We are please to announce our selves as a professional job work Contractor for carrying out surface blasting (Cleaning) service work through The surface is first treated by sharp-edged abrasives – corundum or garnet. abrasives blasting, Sand blasting, Ceramic Blasting, Glass Blasting, The surface is unified and cleaned from any dirt, heat tint after welding, and light surface inconsistencies. At this stage treated components gain opaque look. abrasives sand blasting, The surface is unified and cleaned from any dirt, heat tint after welding, and light surface inconsistencies. At this stage treated components gain opaque look. at the best results are reached in a so called two-stage process.

Vishwash Ceramic Industries Sandblast Services - Jobwork Hardware & Auto Engine Parts Product

Sand Blasting Auto Parts Before & After

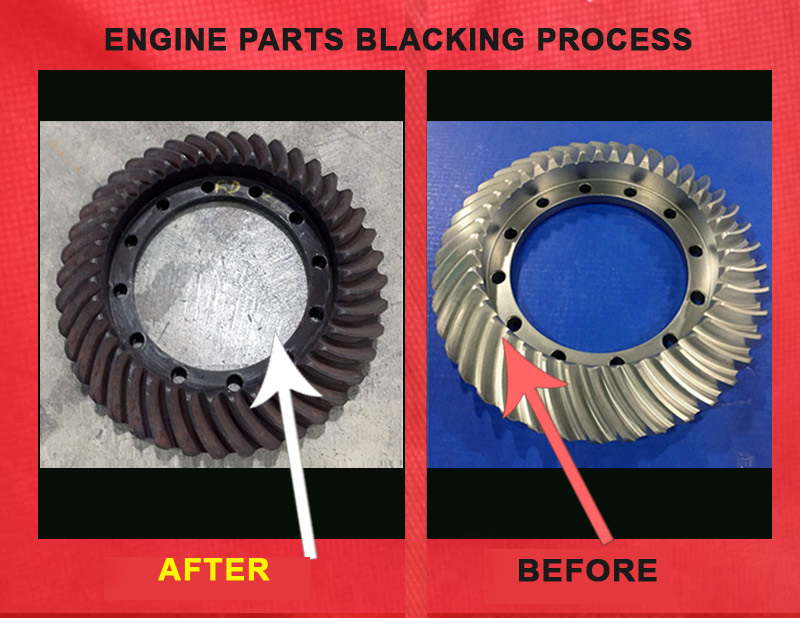

Blanking Shine Process Gear Auto Engine Parts

Sand Blasting Services Engine Parts

Sand Shot Blast Services Auto Parts

Blanking Services Auto Parts Before & After

Glass Blasting Beads Shine Before & After

Ceramic Blasting Beads Services Before After

Blanking Services Engine Part Before & After

Auto Engine Parts Sand Blasting Services